The effect of various sintering temperatures towards microstructural of GdIG has not been carried out in the previous research, which can provide the information on the fundamental knowledge of magnetic behaviour from nanometer to micrometer grain size regime. Therefore, the relationship between microstructural evolution from nano to micron grain size and their physical, magnetic, electrical and microwave properties of the gadolinium iron garnet (Gd3Fe5O12, GdIG) has been investigated systematically. Raw materials were milled using mechanical alloying method for 3 hours, shaped into toroid and pellet and sintered from 600oC to 1400oC with a 100oC increment.

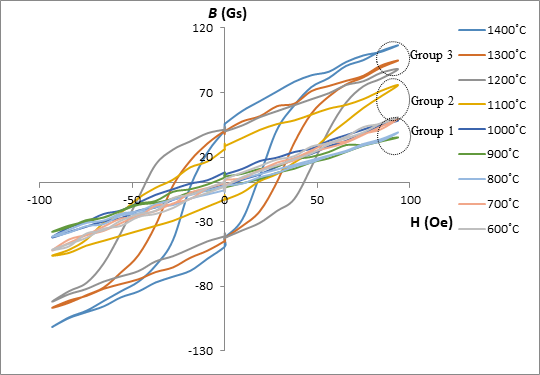

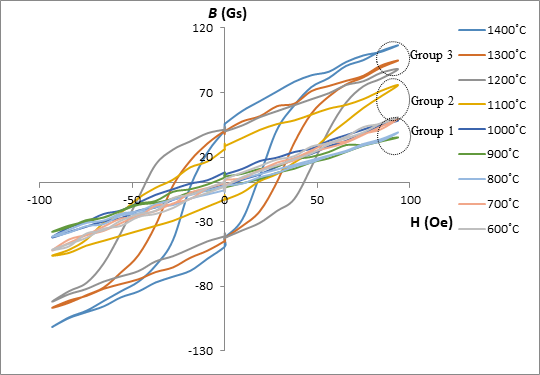

The average particle size measured after milling using Scanning Transmission Electron Microscope (STEM) was ~36.9 nm. GdIG phase which was identified using X-ray diffraction (XRD) began to form a single phase with cubic garnet structure at 1000oC. At this temperature, magnetization studied using vibrating scanning magnetometer (VSM) had started to show an improvement with highest magnetization value of 3.86 emu/g. The Curie temperature (Tc) obtained which was measured using LCR (Inductance, Capacitance and Resistance) meter for GdIG was ~300oC. As the sintering temperature increased, the crystallinity improved with the highest intensity of XRD peak for sample of 1000oC. The microstructure evolution observed using Field Emission Scanning Electron Microscope (FESEM) had influenced the changes in magnetic, microwave and electrical properties. For magnetic measurement, the maximum value obtained through impedance analyser for permeability was 1.33 and the highest induction value of 108.9 G was obtained using B-H static hysteresis graph. The density which was measured using densimeter, observed to be increased at higher sintering temperature with the maximum value of 6.01 g/cm3 for sample sintered at 1400oC. The resistivity value that was measured using picoammeter showed a maximum value for sample sintered at 1200oC of 4.18 1010 Ω cm. The linewidth from microwave measurement that was carried out using Vector Network Analyzer (VNA) in the frequency range of 4 to 8 GHz (C-band), showed the maximum value of 25.10 Oe which validates the suitability for low loss microwave material.

Therefore, the microstructure evolution of starting powder from nanosize grain would allow one to observe the critical change in transformation of phase and also the change in grain size that influenced the change in the properties studied. Samples with good crystallinity and large grain size would result in better properties.

Figure 1. Hysteresis loop formation of samples sintered from 600 to 1400 oC

*Abstract of the thesis (Master) by Farah Nabilah Shafiee

For further information please contact:

Dr. Raba'ah Syahidah Azis, PhD

Chairman

rabaah@upm.edu.my

Date of Input: 25/02/2022 | Updated: 07/10/2022 | roslina_ar

MEDIA SHARING