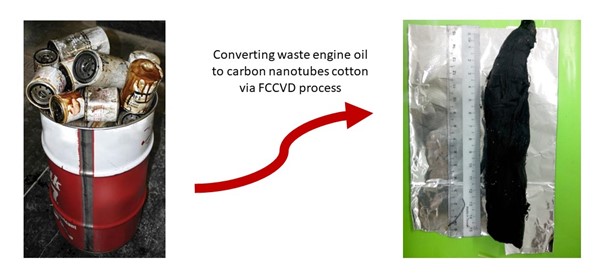

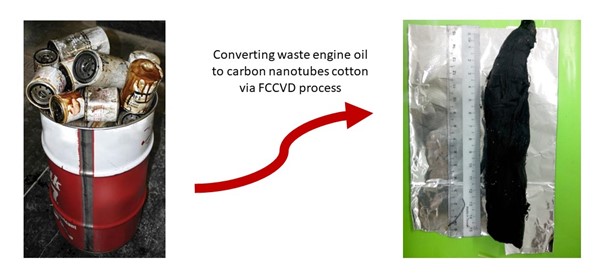

In the pursuit of sustainable solutions to combat environmental challenges, scientists have embarked on a transformative journey that could revolutionize the way we perceive and manage waste. At the forefront of this green revolution is the pioneering effort to convert used engine oil, a notorious environmental pollutant, into a futuristic material known as Carbon Nanotube (CNT) cotton. This groundbreaking process not only addresses the environmental menace posed by discarded engine oil but also introduces a new paradigm for sustainable materials with diverse applications.

The synthesis of CNT) cotton from waste engine oil opens up a realm of innovative applications, notably in the smart textile industry. The CNT cotton, with its lightweight and porous structure composed of randomly aligned CNTs, can be incorporated into cotton-based materials, transforming conventional textiles into advanced and multifunctional fabrics. The exceptional mechanical strength, thermal conductivity, and electrical properties of CNTs enhance the performance characteristics of cotton textiles, offering unprecedented opportunities for the development of smart and functional clothing. From lightweight yet durable outdoor apparel to textiles with built-in sensors for health monitoring, the application of CNT cotton in cotton-based fabrics represents a sustainable and revolutionary leap in the realm of high-performance textiles, fusing environmental consciousness with cutting-edge technology.

Our story begins with an exploration of the intricate composition of waste engine oil (WEO). Once considered a liability, this dark and viscous substance reveals itself to be a complex mixture of hydrocarbons with intricate molecular structures. Researchers meticulously dissect WEO, uncovering a blend of aliphatic and aromatic hydrocarbons, each with its distinct molecular weight and unique properties. As we delve into the scientific intricacies of WEO, it becomes evident that this seemingly problematic substance holds the key to a greener and more sustainable future. The journey from understanding the composition of WEO to harnessing its latent potential is a testament to scientific curiosity and the pursuit of innovative solutions. Before the alchemical transformation of WEO takes center stage, it is imperative to comprehend the gravity of the environmental menace posed by used engine oil. The irresponsible disposal of this ubiquitous waste contributes to environmental degradation, affecting ecosystems and communities worldwide. Painting a vivid picture of the detrimental effects of used engine oil, our narrative underscores the urgency of finding sustainable and innovative solutions to tackle this issue. It sets the stage for a scientific exploration that seeks not only to mitigate environmental impact but also to turn a once-discarded material into a valuable resource.

The scientific odyssey continues as researchers employ fractional distillation to unravel the hidden treasures within waste engine oil. This meticulous process yields five distinct fractions, each representing a segment of the complex hydrocarbon mixture. Temperature ranges, volume percentages, and unique characteristics of each fraction are meticulously examined, laying the groundwork for the subsequent transformation. Fractional distillation becomes the alchemist's tool, separating the lighter hydrocarbon molecules from their heavier counterparts. The resulting fractions, each with its unique properties, become the building blocks for a sustainable future. The distillation process not only refines the components but also showcases the versatility hidden within the seemingly homogeneous mixture of waste engine oil. With the fractions unveiled, scientists delve into the properties that make each segment unique. Density and viscosity take center stage as indicators of the composition of these fractions. The revelation that these fractions possess lower density and viscosity than the original waste engine oil becomes a pivotal point in the narrative. The Carbon–Nitrogen-Sulfur (CNS) analysis provides a deeper understanding of the elemental composition of each fraction, emphasizing the high carbon content. This newfound knowledge sets the stage for the subsequent synthesis of CNT cotton, where the lighter hydrocarbon components play a crucial role in shaping the material's characteristics.

Before the alchemical transformation takes place, researchers explore suitable reaction conditions for the synthesis of CNT cotton. This phase of the journey involves navigating the challenges inherent in the Floating Catalyst Chemical Vapor Deposition (FCCVD) approach. The temperature, injection rates, and choice of carrier gas emerge as critical factors in ensuring the success of the synthesis. Through numerous experiments, the researchers unveil the optimal conditions for the synthesis process. The injection rate of the reactant and the application of hydrogen as a carrier gas become key determinants in the success of the transformation. The delicate balance between reactant availability and catalyst efficiency shapes the path toward a sustainable and efficient synthesis process. Finally, the culmination of the scientific journey is reached as waste engine oil fraction 1 becomes the catalyst for the synthesis of CNT cotton through FCCVD. The resulting cotton exhibits a lightweight, black, and porous structure composed of randomly aligned CNTs. This synthesis represents a triumph in turning a once-polluting substance into a high-tech material with diverse applications. The characterization of the CNT cotton provides a comprehensive understanding of its structure and properties. High-Resolution Transmission Electron Microscopy (HRTEM), Energy Dispersive X-ray Spectroscopy (EDX), Thermal Gravimetric Analysis (TGA), and Nitrogen Adsorption analyses offer a glimpse into the morphology, purity, and thermal characteristics of the synthesized aerogel.

In conclusion, the synthesis of CNT cotton from waste engine oil signifies a paradigm shift in waste utilization. This scientific endeavor not only addresses the issue of used engine oil pollution but also showcases the transformative potential of repurposing waste materials. From pollution to innovation, the journey narrated in this article exemplifies the convergence of environmental consciousness and technological innovation. The successful transformation of waste engine oil into CNT cotton not only mitigates environmental impact but also lays the foundation for a future where waste becomes a valuable resource for advanced technologies. As we celebrate this scientific triumph, it is essential to recognize the broader implications of this research. The transformation of waste engine oil into a high-tech material hints at a future where waste materials serve as the building blocks for sustainable practices and advanced technologies. This journey represents a significant step toward a circular economy, where waste is not a problem to be managed but a resource to be harnessed. In a world grappling with waste management challenges, this scientific breakthrough stands as a beacon of hope and inspiration. The narrative of turning waste engine oil into CNT cotton is not just a scientific achievement; it is a testament to the power of innovation in shaping a sustainable and enlightened future. As we look ahead, the lessons learned from this journey will undoubtedly guide us toward a greener and more sustainable tomorrow.

Source:

Hayder Baqer Abdullah, Ramli Irmawati, Ismayadi Ismail, Nor Azah Yusof, Utilization of waste engine oil for carbon nanotube aerogel production using floating catalyst chemical vapor deposition, Journal of Cleaner Production, Volume 261, 2020, 121188, ISSN 0959-6526, https://doi.org/10.1016/j.jclepro.2020.121188. (https://www.sciencedirect.com/science/article/pii/S095965262031235X)

Date of Input: 27/11/2023 | Updated: 27/11/2023 | roslina_ar

MEDIA SHARING