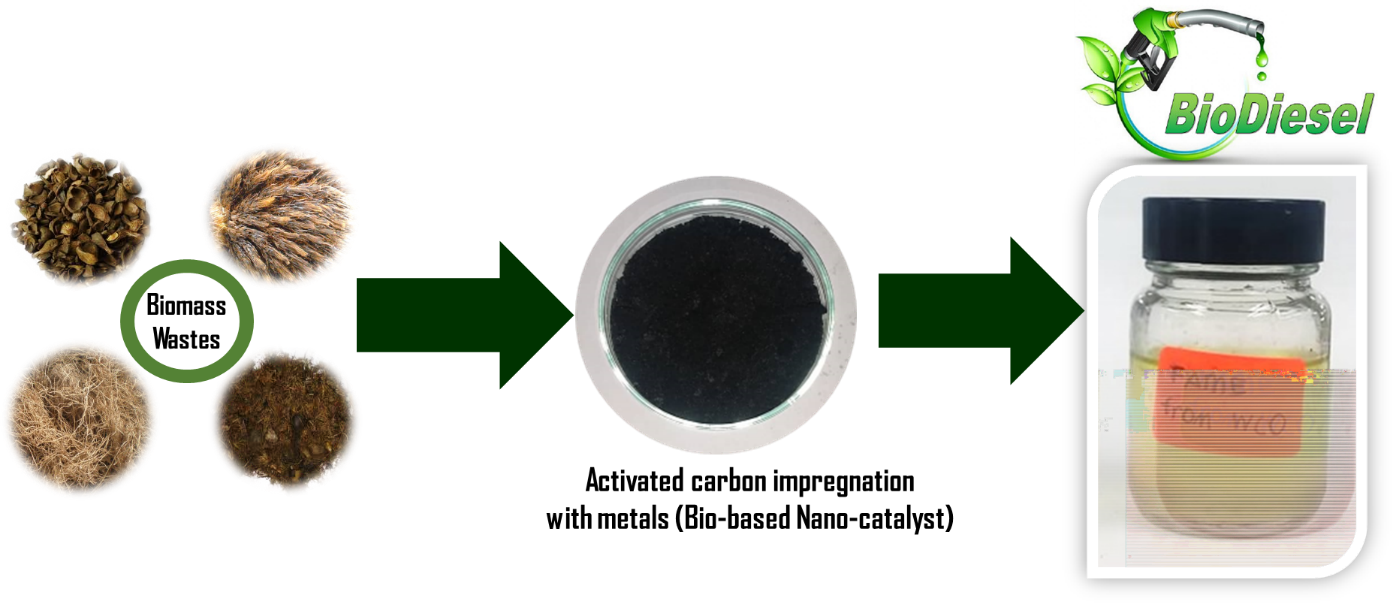

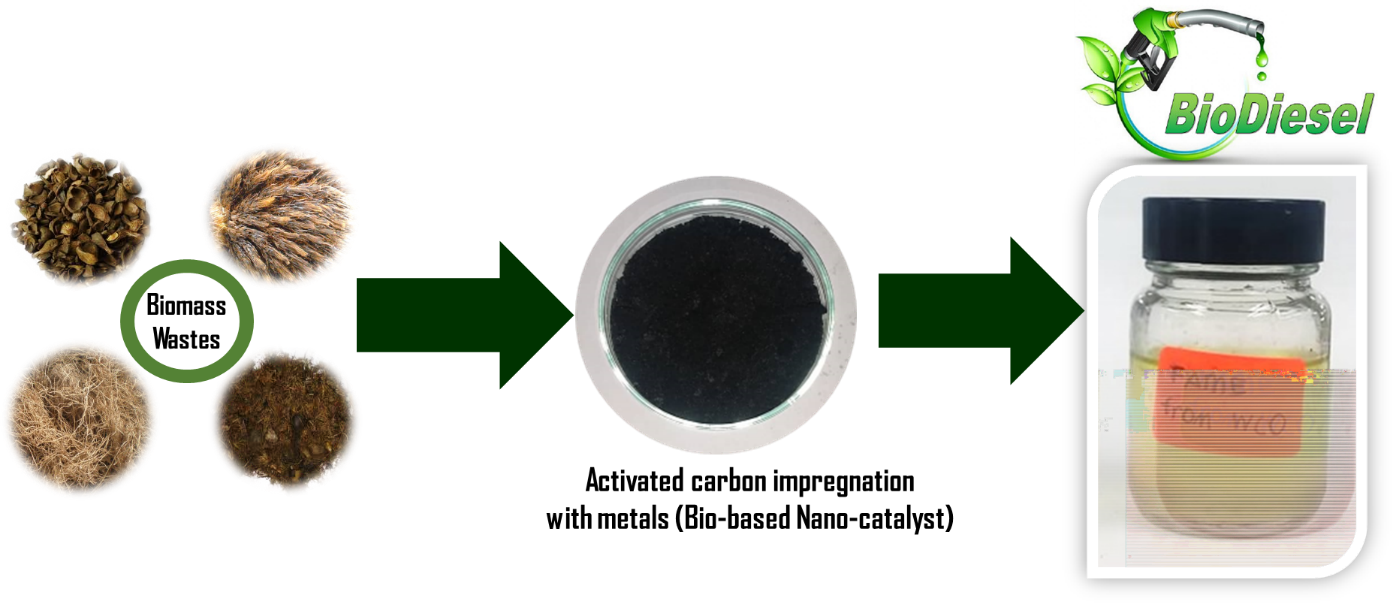

Biodiesel is an alternative diesel fuel consisting of alkyl monoesters of fatty acids derived from vegetable oils or animal fats. Currently, most of the biodiesel is made from food oils; however, there are several other potential resources such as waste vegetable oil (WVO) and palm fatty acid distillate (PFAD) which could be explored for biodiesel production. This process, namely esterification and/or transesterification, require an effective catalyst to accelerate the process. The objectives of our research are to evaluate the feasibility of biodiesel production using low-cost of non-food oil feedstock and to synthesize a reusable, efficient, and effective biobased catalysts from agriculture waste.

Recently, the designation of catalyst from biomass-based-waste to produce activated carbon is the best option to ensure environmental sustainability including 80% overall cost reduction. This activated carbon is then functionalized with metals of choice on its surface as active sites to provide a specific function, where this feature gives a new identity as a catalyst for many applications. Our research focuses on producing activated carbon with a high surface area to provide extra space for active sites. As a result, the catalysts have a high concentration of basicity and/or acidity to give maximum yield. We have made efforts to produce a highly porous activated carbon through hydrothermal carbonization (HTC).

Basically, HTC is a compilation of several processes, namely hydrolysis, dehydration and decarboxylation of the hydrolyzed products and simultaneous polymerization and aromatization that will finally produce solid bio-crude. Other than that, the auto-generated inner pressure facilitates hydrolysis of organic compounds and fabricating a high degree of aromatization that contains roughly 40–90% of the mass with more than 80% of the fuel value compared to the original biomass feed. Besides, HTC is an environmental-friendly method with many advantages, especially when dealing with wet materials. In addition, there is no pre-drying step involved, and water as the solvent has a significant economic impact, especially production costs. The process continues with pyrolysis that offers higher porosity and more stable activated carbon especially for storage and transportation. As a result, the activated carbon with a BET surface area of more than 4000 m2/g has provided a high concentration of basicity and acidity to produce maximum biodiesel from waste cooking oil.

Furthermore, the prepared catalyst also demonstrated a remarkable reusability profile up to the fifth reaction cycles with more than 50% of biodiesel yield up to sixth reaction cycle. The bifunctional bio-based catalyst prepared from the HTC-assisted technique has great potential for the conversion of high FFA feedstock, especially WCO, to biodiesel. Furthermore, the quality attributes and performance of the biodiesel produced is evaluated and compared with specified standards and petroleum diesel.

Ts. Dr. Umer Rashid, M.I.M.M.

Fellow Researcher (MPTL)

umer.rashid@upm.edu.my

Date of Input: 11/06/2021 | Updated: 11/06/2021 | nursyahirah

MEDIA SHARING