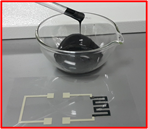

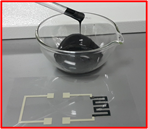

Have you been wondering if electronic circuits can be printed onto clothes or papers? The answer is yes, they can! Thick film technology is widely used to produce electronic devices due to its ease of fabrication. The technology utilizes a screen printing method, which is the same method used to print designs on textiles such as t-shirts. Thick films are fabricated by printing a circuit design onto a substrate using a thick film paste, which is in a form of a highly viscous liquid that includes materials which determine the properties of the thick film. However, conventional pastes require high temperatures to bind the active materials to the substrate, and this makes them not suitable for use in printed flexible electronics, since the flexible substrates such as plastic films, papers and textiles cannot withstand high temperatures.

Our research project has been focusing on the innovation on the use of linseed oil as the organic binder or commonly called an organic vehicle to produce thick film paste that can be dried or fired at lower temperatures as compared to the conventional pastes. Linseed oil is often used as drying oil in paintings since it has a boiling point of 346°C, making it suitable to be used for lower firing temperature. Linseed stand oil has higher viscosity compared to raw linseed oil, making it more suitable as the organic binder.

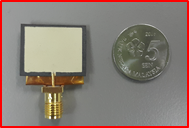

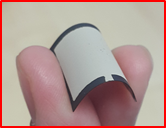

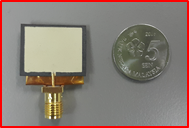

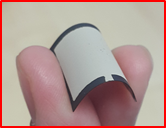

With this innovation, we can produce thick film pastes that can be fired at temperatures lower than 300°C, and still having significant properties related to the active materials used. One example is the use of ferrite thick film to enhance the performance of patch antenna, specifically the bandwidth of the antenna. When the thick film is layered in between a polymer film which acts as the substrate, and a silver patch that will radiate antenna’s signal, it has proven to widen the bandwidth by more than 30%. This is a significant improvement for patch antenna which is always known to have issues with narrow bandwidth, and at the same time promoting potential fabrication of flexible or wearable antennas in the near future.

Dr. Intan Helina Hasan

Research Officer

Functional Devices Laboratory (FDL)

Institute of Advanced Technology, UPM

i_helina@upm.edu.my

Date of Input: 11/06/2019 | Updated: 07/10/2022 | roslina_ar

MEDIA SHARING